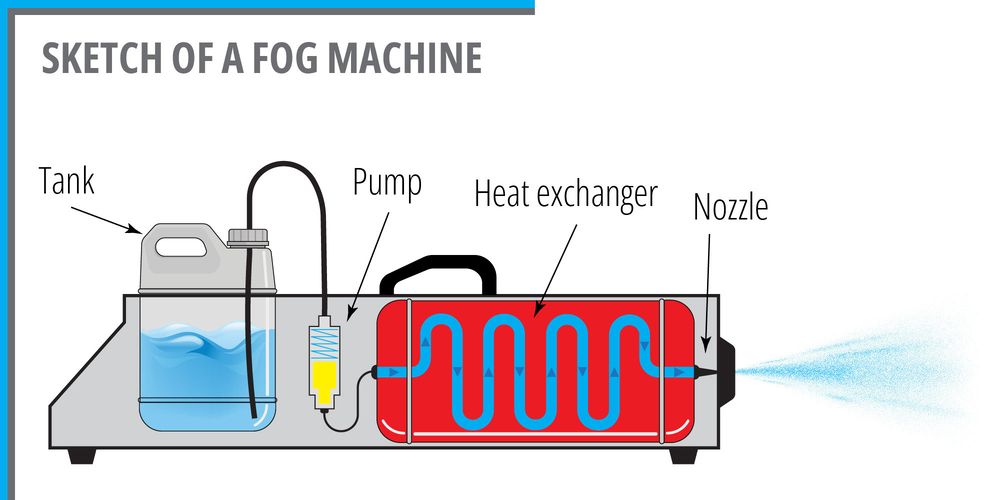

3. Operating principle

Using the following brief example, we'll describe the operation of a "simple" fog machine.

Tank

Every fog machine features a storage container or tank. Its volume is normally indicated among the details on the spec sheet, and usually depends on the capacity of the machine in turn. More powerful machines logically require larger tanks to avoid the necessity of frequent refills (maybe even during a stage production).

Pump

When you start the fog generation using your remote control, the pump goes into operation, and it keeps operating as long as the "start" button remains depressed and the heat exchanger is sufficiently hot. If the heat exchanger cools down too much, fog generation is interrupted. The fog solution is pumped from the tank into the heating chamber.

Heat exchanger

This is the most important element of a fog machine. Various safety circuits make sure that the exchanger does not overheat and that no fluid is pumped into the heating chamber before it is at operating temperature or when it cools down too much. Once operating temperature has been reached, the machine is ready for operation. This is most often indicated by a light on your remote control.

Nozzle

As the fluid encouters the heat exchanger, it is immediately vaporised. The fog exits the nozzle at the front of the instrument at high speed - be careful, this steam is quite hot! Depending on the fluid's composition, the fog may be dense and linger, or it may be more misty, hazy. Fog can also be cooled directly using an additional cooling unit, which results in fog that lies close to the groupd, similar to the effect achieved by vaporising dry ice.